The technical parameters of the manipulator reflect the competent work of the manipulator and the highest operational performance. It is a problem that must be considered in the selection, design and application of the manipulator. Rubber injection molding machine automation

The main technical parameters of the manipulator usually include the following seven:

(1) Degree of freedom

(2) Resolution

(3) Precision

(4) Repeat positioning accuracy

(5) Scope of work

(6) Carrying capacity

(7) Maximum speed

The working range of the manipulator refers to the collection of all the points that can be reached at the end of the arm or the center of the wrist, also called the working area.

Since the shape and size of the end effector are various, in order to truly reflect the characteristic parameters of the manipulator, the working range refers to the working area when the end effector is not installed. The rubber injection molding machine is automated

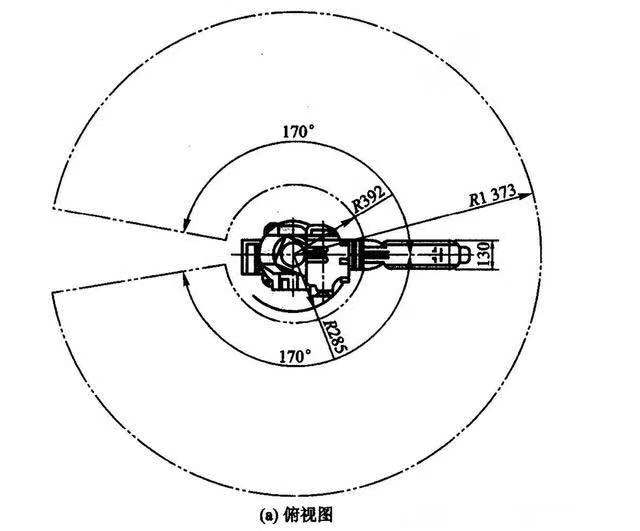

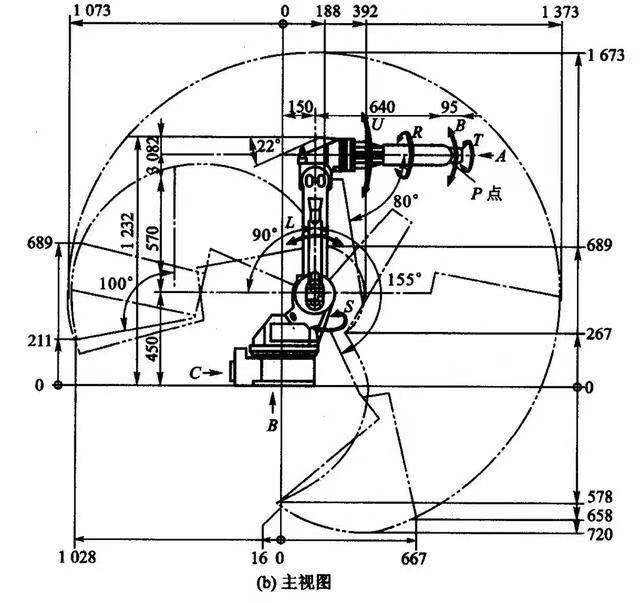

The shape and size of the working range are very important. The robot may not be able to complete the task due to the dead zone that cannot be reached by the hand when performing a certain task. The following figure shows the working range of MOTOMAN UP6 manipulator.

The most common industrial manufacturing robot is a robotic arm. A typical robotic arm consists of seven metal parts connected by six joints. The computer will rotate a stepping motor connected to each joint separately to control the manipulator (some large robotic arms use hydraulic or pneumatic systems). Unlike ordinary motors, stepping motors move precisely in increments. This allows the computer to accurately move the robotic arm so that the robotic arm repeats the exact same actions continuously. The manipulator uses motion sensors to ensure that it moves exactly the correct amount.

This six-joint industrial manipulator is very similar to a human arm. It has parts equivalent to shoulders, elbows, and wrists. Its "shoulder" is usually mounted on a fixed base structure (rather than a moving body). This type of manipulator has six degrees of freedom, that is, it can rotate in six different directions, and its working range is quite large. The rubber injection molding machine is automated.