The manipulator is an active operating device that can imitate certain actions of human hands and arms to grasp, transfer or manipulate objects according to a fixed procedure. The feature is that it can be programmed to complete various expected tasks, and its structure and function have both the strengths of human and mechanical handpieces.

Manipulators are the earliest industrial robots and modern robots. They can replace human labor to complete the mechanization and automation of production, and can operate in harmful environments to protect personal safety. Therefore, they are widely used in mechanical production and metallurgy. , Electronics, light industry and atomic energy.

In today's life, with the rapid advancement of science and technology, the biggest difference between a robotic arm and a human arm lies in its sensitivity and endurance. That is, the biggest advantage of the manipulator is that it can do the same action repeatedly, and it will never feel tired under normal mechanical conditions! The use of manipulators will become more and more widespread. Manipulators are a high-tech active production equipment developed in recent decades. The accuracy of operations and the ability to complete operations in the environment. An important branch of industrial manipulator robots.

According to the driving method, it can be divided into hydraulic, pneumatic, electric, and mechanical. The feature is that it can be programmed to complete various expected tasks, and its structure and function have both the strengths of human and mechanical handpieces.

constitute

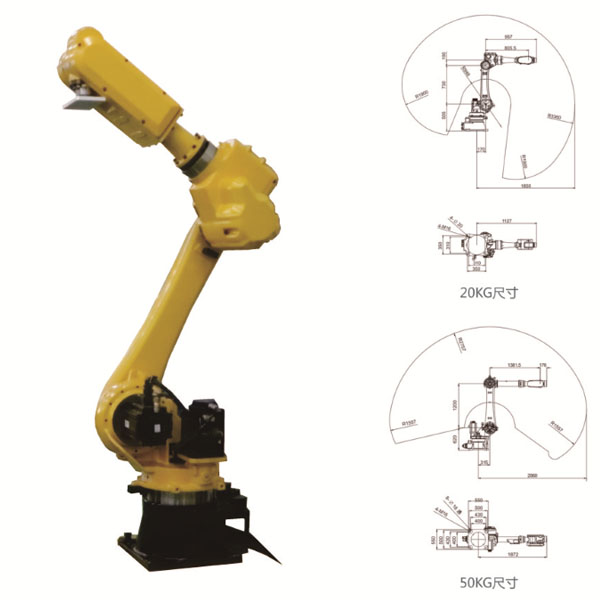

The manipulator is mainly composed of three parts: executive organization, driving organization and control system. The hand is a component used to hold a workpiece (or something). According to the shape, size, weight, data and operation requirements of the object to be grasped, it has a variety of structural forms, such as clamping type, holding type and adsorption type, etc. . The movement organization enables the hand to complete various rolling (swinging), moving or compound movements to complete regular movements, and to change the position and posture of the object being grasped. The independent movement methods such as lifting, elasticity, and rotation of the moving tissue are called the freedom of the manipulator. In order to grasp objects in any position and orientation in space, 6 degrees of freedom are required. Freedom is a key parameter for manipulator planning. The greater the degree of freedom, the greater the sensitivity of the manipulator, the wider the versatility, and the more messy its structure. Generally, the dedicated manipulator has 2 to 3 degrees of freedom. The control system is through the control of the motor of each degree of freedom of the manipulator to complete a specific action. Receive the information from the sensor together to form a stable closed-loop control. The core of the control system is generally composed of a micro-control chip such as a single-chip microcomputer or dsp, and the necessary functions are completed after its programming. Silicone rubber machinery automation

The executive organization of the manipulator is divided into hands, arms, and torso;

1. Hands

The hand device is at the front of the arm. The inner hole of the arm is equipped with a transmission shaft, which can transfer the application to the wrist to roll, stretch the wrist, and open and close the fingers.

The structure of the manipulator hand is modeled on a human finger, and is divided into three types: no joints, fixed joints and free joints. The number of fingers can be divided into two fingers, three fingers, and four fingers, among which two fingers are the most used. According to the shape and size of the clamping object, it can be equipped with various shapes and sizes of chucks to get used to the needs of operation. The so-called hands without fingers generally refer to vacuum suction cups or magnetic suction cups.

2. Arm

The function of the arm is to guide the fingers to accurately grasp the workpiece and transport it to the desired position. In order for the manipulator to work correctly, the three degrees of freedom of the arm must be accurately positioned.

3. Trunk The torso is the scaffold of the equipment arm, power source and various executive organizations [1].

Drive organization

There are four main types of drive organizations used by the manipulator: hydraulic drive, pneumatic drive, electrical drive and mechanical drive. Among them, hydraulic drive and pneumatic drive are most used.

1. Hydraulic drive

Hydraulically driven manipulators generally consist of a hydraulic motor (various oil cylinders, oil motors), servo valves, oil pumps, oil tanks, etc., which form a drive system, and the manipulator drives the manipulator to perform organization and work. Generally, it has great snatch ability (up to several hundred kilograms). It is characterized by compact structure, smooth movement, impact resistance, sensation resistance, and good explosion-proof performance. However, hydraulic components require high production accuracy and sealing function. Otherwise, the oil spill will pollute the environment.

2. Air driven

The drive system is generally composed of air cylinders, air valves, air tanks and air compressors. It is characterized by convenient air source, quick action, simple structure, low cost, and convenient repair. But it is difficult to control the speed, and the air pressure is not too high, so the snatch ability is low. Silicone rubber machinery automation

3. Electric drive electric drive is the most commonly used drive method for manipulators. It is characterized by convenient power supply, quick response, large driving force (articulated robustness has reached 400kg), convenient signal detection, transmission, and processing, and a variety of sensitive control schemes can be selected. The driving motor is generally a stepping motor, and the direct current servo motor (AC) is the primary driving method. Due to the high speed of the motor, a reduction organization (such as harmonic drive, RV cycloid pinwheel drive, gear drive, spiral drive, and multi-rod organization, etc.) is generally required. Some manipulators have begun to use high-torque, low-speed motors with no deceleration organization for direct drive (DD), which can simplify the organization and improve the control accuracy.

4. Mechanically driven

Mechanical drive is only used for occasions with fixed movements. Generally, the cam link organization is used to complete the regular actions. It is characterized by reliable action, high operating speed and low cost, but it is not easy to adjust. There are also optional hybrid drives, that is, liquid-gas or electric-hydraulic hybrid drives.

Control system

The elements of manipulator control include work sequence, arrival direction, action time, movement speed, acceleration and deceleration, etc. The manipulator control is divided into two types: point control and continuous orbit control. Silicone rubber machinery automation

The control system can be planned to use digital sequence control according to the requirements of the action. It must first compile a program to store it, and then according to the rules of the program, there are two storage methods for manipulating the manipulator to store the operating program: separate storage and collective storage. Separate storage is the separate storage of information of various control elements in more than two storage devices, such as sequence information stored in latch plates, cam drums, perforated belts; position information is stored in time relays, constant-speed rotating drums, etc.; Gathering storage is to store all the information of various control elements in a storage device, such as magnetic tape, magnetic drum, etc. This method is used in situations where it is necessary to control the sequence, position, time, speed, etc. together, that is, in the case of successive control.

In the meantime, the latch board is used in occasions that require agile changes to the program. To change a program, you only need to change a plug board, and the same plug-in can be reused; the length of the program contained by the punched tape is not limited, but if an error occurs, it must be replaced in full; the information capacity of the punched card is limited, But it is easy to replace, save, and can be reused; magnetic cores and drums are only suitable for occasions with large storage capacity. As for which kind of control element to choose, it is judged according to the messy procedure and accurate procedure of the action. For manipulators with chaotic motions, use a reproducible control system for advice. More messy manipulators use digital control systems, small computers or microprocessor control systems. The control system is the most used pin plate, followed by the cam drum. It is equipped with many cams, and each cam is assigned to a motion axis, and the drum moves in one cycle to complete a cycle.

Classification

The types of manipulators can be divided into hydraulic, pneumatic, electric, and mechanical manipulators according to the driving method; according to the scope of application, they can be divided into special manipulators and general manipulators; according to the motion track control method can be divided into point control and continuous connection Rail control manipulators, etc. Manipulators are generally used as additional equipment for machine tools or other machines, such as loading and unloading and transferring workpieces on active machine tools or active production lines, and replacing tools in machining centers. Generally, there is no independent control device. Some operating equipment needs to be directly operated by humans. For example, the master-slave operator used for nuclear energy to handle dangerous goods is often called a manipulator. The use of manipulators in the foundry industry can further develop the production capabilities of foundry equipment and improve working conditions such as heat and fatigue.

The manipulator was first developed from the United States. In 1958, the United States United Control Company developed the first manipulator.

Advantage

Manipulators can save workers, improve power, reduce costs, improve product quality, improve safety, and improve the image of the factory.

The advantages of multi-joint manipulators are: sensitive movements, small inertia of movement, strong versatility, ability to grasp workpieces close to the machine base, and ability to bypass obstacles between the machine body and the work machine. The sensitivity, positioning accuracy and working space of the articulated arm have put forward higher and higher requirements. The multi-joint arm also breaks through the traditional concept. The number of joints can range from three to a dozen or more. Its shape is not limited to a human-like arm, but varies according to different occasions. The multi-joint arm is excellent The functions cannot be compared with single-joint manipulators. Silicone rubber machinery automation