Rubber machinery is mainly used in the production process of tires, cables and wires, tapes, hoses, rubber shoes and other rubber products. Tire manufacturing machinery such as tire building machines and tire vulcanizers account for more than 60% of the total market size of the rubber machinery industry.

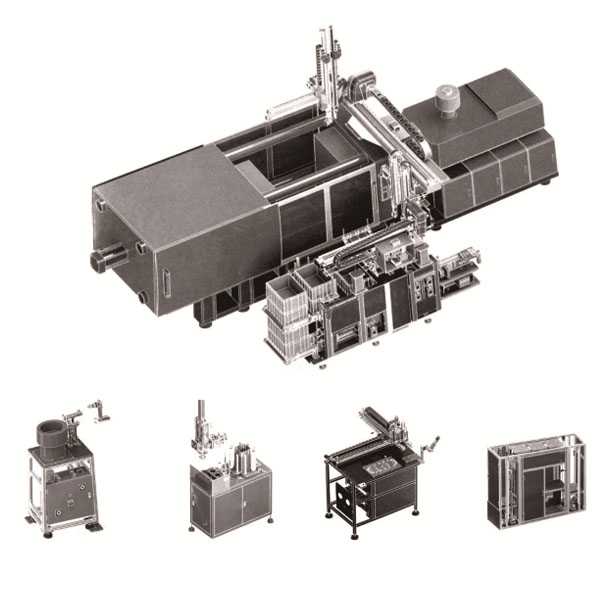

The tire production process generally has six major processes such as mixing, extrusion, calendering, cutting, molding and vulcanization, and each stage of the process has a corresponding internal mixer, extruder, calender, cutting machine, and molding machine. And vulcanizers and other major rubber machinery.

Rubber machinery automation products are mainly control system products and drive products. The demand for these two categories of products accounts for about 50% of the overall rubber machinery industry automation market, while the automation products such as motion control/discrete sensors, feedback components and actuators The market demand is relatively small.

The control system products in rubber machinery are mainly PLC, HMI (human-machine interface) and IPC (industrial computer); rubber machinery mainly uses PLC controllers, and embedded dedicated controllers and relays are rarely used. From the perspective of PLC application, the control of molding machines and vulcanizers is more complicated, requiring precise control of various parameters such as position, temperature, pressure, and speed, so a large number of PLCs are required. However, the control of rubber machinery such as extruders, calenders, and cutting machines is relatively simple. Generally, a small PLC with analog I/O can meet the requirements.

Among the drive products, the rubber machinery industry mainly uses low-voltage inverters, followed by DC drives. In internal mixers and calenders, there are many applications of DC speed control systems, and other machines are mainly driven by frequency converters.