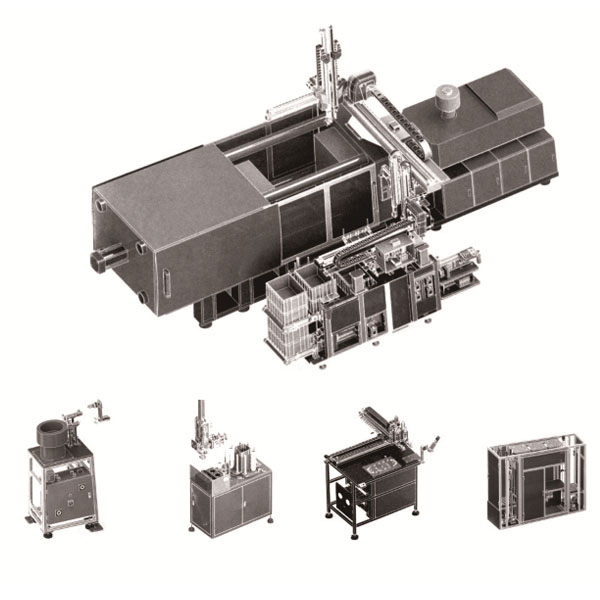

The truss type manipulator is also known as the gantry type manipulator. It is made of profile or square steel as the main structure, inlaid with linear sliding guides and gear racks. As the moving structure and carrier, the cross-sectional shape of the refined profile is optimized through the finite element analysis method, and the fine carving during production ensures its strength and straightness. The truss-type manipulator effectively improves the working environment. The supply of parts processing is digitalized, informatized, less humanized and unmanned. It reliably guarantees product quality, greatly improves labor productivity, and saves workers from heavy physical labor. Liberation, bringing modern manufacturing skills to a new level. Kunshan Keshide Automation Machinery Co., Ltd. is an automation manufacturer of rubber injection molding machines.

The truss manipulator is a kind of fully automatic industrial equipment based on the right-angle X, Y, Z three-coordinate system to adjust the work position or complete the trajectory movement of the work piece. Its control center is harmoniously controlled by industrial controllers (such as PLC, motion control, single-chip microcomputer, etc.), and various hydraulic cylinders and air cylinders cooperate for action processing. The entire automatic loading and unloading process consists of five parts: workpiece transportation, manipulator reclaiming, chuck loading and unloading, manipulator feeding and sending parts to the next process. In the meantime, the part where the workpiece is transported and the parts are sent to the next process is executed in parallel with other parts, and the CNC processing is performed in parallel with the robot picking and feeding part and the CNC processing together with the rubber injection molding machine automation.

The truss manipulator has a multi-degree-of-freedom movement, and the space angle between each degree of freedom of movement is a right angle. It is an automatic control device that can be programmed repeatedly, and all movements work according to the program. Generally composed of control system, drive system, mechanical system, operating tools, etc. Flexible, multi-function, because of the different functions of the operating tools, it achieves the characteristics of high reliability, high speed, and high precision in operation, and can be used in harsh environments. It can be operated for a long time and is easy to operate and repair. Rubber injection molding machine automation

Features of truss manipulator: Rubber injection molding machine automation

1. Efficient---The axes work linearly at extremely high speeds, which can be quickly echoed by the servo motor;

2. Stability-----minimal repetitive fault, up to 0.05mm;

3. High-intensity ------ 7x24 hours work, no need to eat, sleep, smoke, etc.;

4. High precision ------ the positioning accuracy can reach 0.02mm (according to the manufacturing cost, the positioning accuracy can be appropriately expanded according to the operating conditions);

5. High performance-price ratio-truss manipulators are more expensive than joint robots, with a heavier load and lower manufacturing costs, which are suitable for the basic national conditions of "Intelligent Manufacturing in my country";

6. Simple operation ------ According to the Cartesian coordinate system, its motion parameters are relatively simple.

Kunshan Keshide Automation Machinery Co., Ltd. mainly produces rubber and plastic machinery automation and peripheral automation equipment. It is a high-tech rubber automation enterprise integrating product development, planning, manufacturing, sales and service. The company’s products are widely used in a variety of tasks, including: home appliance industry, computer and peripheral industry, photoelectric industry, cosmetics industry, automobile industry, wall clock industry, precision gear industry, PET preform industry, beach table and chair industry, audio-visual music industry, guidance Optical panel industry, communication electronics industry, mobile phone industry, medical supplies industry, medicine packaging industry, food packaging industry...etc. Supply high-quality, high-efficiency, and reasonable-priced automation products for rubber machinery automation. Landline: 0512-36807318 Website: www.casend.net Welcome to come to consult.