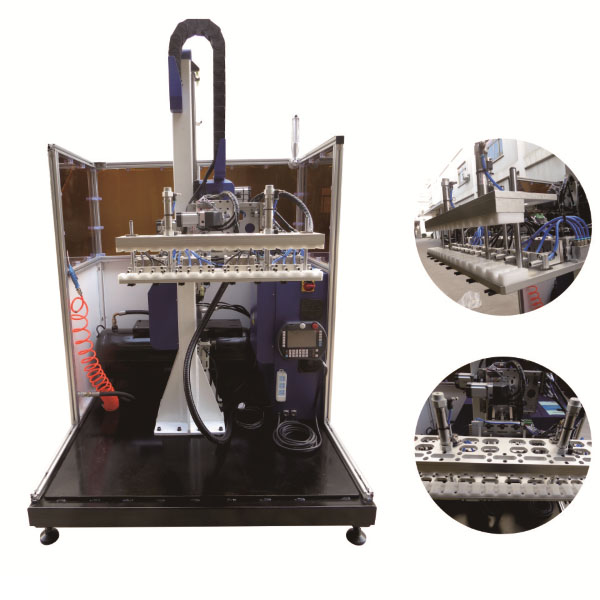

Rubber injection molding machine automation

Structure:

Pneumatic system, cutting system and electronic control system are composed:

1. Extrusion equipment: It is composed of hydraulic cylinder, material barrel and head number.

Stable value to ensure accurate control of the weight of the extruded rubber blank.

Rubber preforming is a plunger type machine, which is mainly composed of extrusion equipment, hydraulic system, vacuum system, water circulation system, electric heating system,

2. Hydraulic equipment: use high-pressure gear pumps and flow valves. The hydraulic oil of the hydraulic cylinder is controlled by the flow valve. The differential pressure valve before and after the throttling is always controlled in one

3. Pneumatic equipment: used to control the opening and closing of the nose.

4. Vacuum system: Before extruding the rubber material, vacuumize it to remove the air inside the barrel and the machine head and the mixed gas in the rubber material, so as to improve the quality of the vulcanized products in the next process.

5. Heating system: The water circulation heating method is selected, and the temperature is controlled and displayed by a digital thermostat. Ensure that the temperature of the machine head and barrel is stable.

6. Cutting equipment: It is composed of frame, motor and deceleration system. The cutting motor selects a frequency converter to achieve stepless speed regulation, and a transmission device is installed in the lower part of the frame.

7. Use high-definition LCD touch screen and PLC to achieve full active control and operation.

8. The electronic scale feedback system is selected for communication control, and the knife speed is actively adjusted to make the cut rubber blank reach the required weight.

Usefulness:

The rubber preforming machine is a kind of high-precision and high-efficiency rubber blank making equipment, which can produce various medium and high hardness, various shapes of blanks, and the blanks have high precision, no bubbles, and are suitable for the production of miscellaneous rubber parts and oil seals. , О ring, tennis ball, golf ball, valve, shoe sole, auto parts, medicine, agricultural granulation and other products.