Manipulators play an important role in industrial production. Manipulators are high-tech products that combine multiple technologies. The use of industrial manipulators is a useful means to improve product quality and labor productivity, to automate the production process, to improve working conditions, and to reduce labor intensity. In the actual operation process of the manipulator, it is necessary to improve the operation function of the manipulator, and carry out scientific and reasonable manipulator planning according to the actual needs of the enterprise.

The hand of the manipulator is the part used to hold the workpiece (or tool). The speed, accuracy and reliability of the hand gripping the workpiece will directly affect the operation function of the manipulator, and it is one of the key parts of the manipulator. More and more factories are beginning to free the hands of workers, and then replace them with robots. The manipulator is generally composed of an execution system, a drive system, a control system and an artificial intelligence system, and it can mainly complete movement, rotation, grasping and other actions.

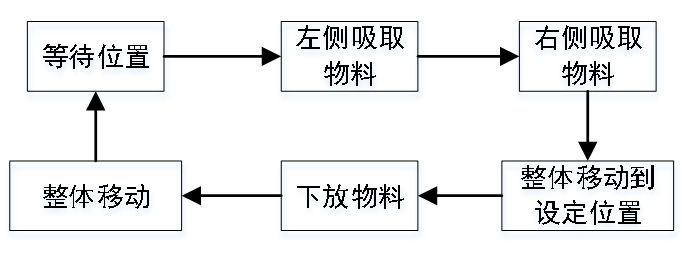

Manipulator structure and work flow

The entire manipulator reclaiming system is mainly composed of connectors, left and right cylinders, fixed chambers, air pipe joints and end suction cups. The left and right cylinders are dual-effect cylinders; the fixed cavity has the effect of connecting and fixing, the air pipe joint and the suction cup are connected to the cylinder together, and the cavity in the center can be a suction cup that can communicate with the air pipe.

The specific operation process of the manipulator system is: the initial position of the manipulator is that the left and right cylinders are retracted. When the system recognizes the material, the left part moves to the top of the material, the left cylinder extends, and the air pipe is connected to vacuum. The left suction cup is evenly pressed on the material to suck the material. After sucking the material, the cylinder retracts, and the right cylinder repeats the left action. After both sides absorb the material, all move to the specified position at the end, the air pipe is switched to compressed air, and the gas is filled with the air pipe The material can be blown down and placed in the specified position. So far, the manipulator system has completed a reclaiming cycle.

With the continuous development of the manufacturing industry, more and more factories and enterprises are beginning to deploy automated production lines, and the manipulator as a kind of actuator can be said to be an indispensable part of the automated production line.